About

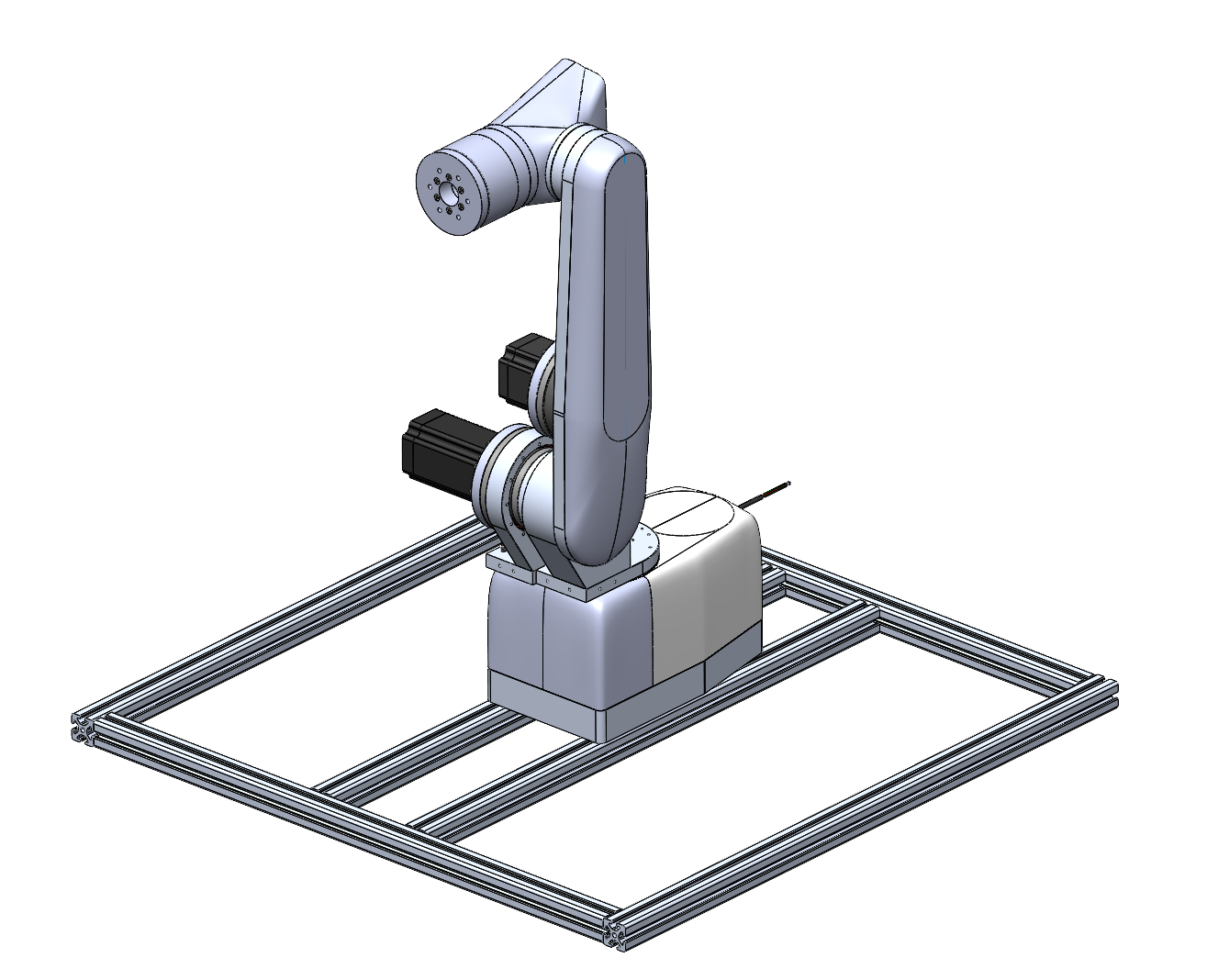

IRAS is my self-made robot arm, designed to have a large work envelope and high carrying capacity. With IRAS I compete at Jugend-Forscht, a German science competition. Many parts are made from machined aluminium and 3d-printed.

IRAS is used to do research regarding intuitive control of industrial robotic arms. IRAS won’t be a stand alone robot arm but rather a system of the IRAS arm itself and many accessories for easy and intuitive control. However the foundation for my research is a capable robotic arm.

This robot arm is the second one I build, with the old one beeing fully 3d-printed, but still fairly large. With IRAS I want to achieve a carrying capacity of over 8kg with a work envelope exceeding 1 metre and a sub millimetre repeatability.

(Disclaimer: This project is still in an early stage, and files aren’t accessible yet. The competition will be in the first quarter of 2026. This webiste will be constantly updated, as soon as new content is available)

WORK IN PROGRESS!

Design Overview

IRAS is designed to be a capable industrial robot arm, and therefore has 6-DoF.

I knew, that 3d-printed actuators for a robot of this size aren’t good enough (for the first three joints). The 3d-printed cycloidal actuators I built for my first ever robotic arm lacked precision, strenght and overall stiffness, eventhough the old one was smaller and lighter, than IRAS will be.

I therefore reached out to Nabtesco, a leading producer of strain wave gears. They were kind enough to provide me with two zero-backlash strain wave reducers. I bought a third used drive for the first joint. The first three joints of the robot were therefore relatively easy to design.

I decided to make all arm segments only be connected on side, so that the robot is easy to disassemble and be transported.

A further design consideration was the construction, especially the placements of the joint five, six and seven motors, of the upper arm. I decided to place all 3 motors behind the pivot point of the 3rd joint, therefore decreasing the leverage and stress on the arm. The placement also allowed the arm to have a lower moment of inertia and higher payload capacity, though a higher complexity.

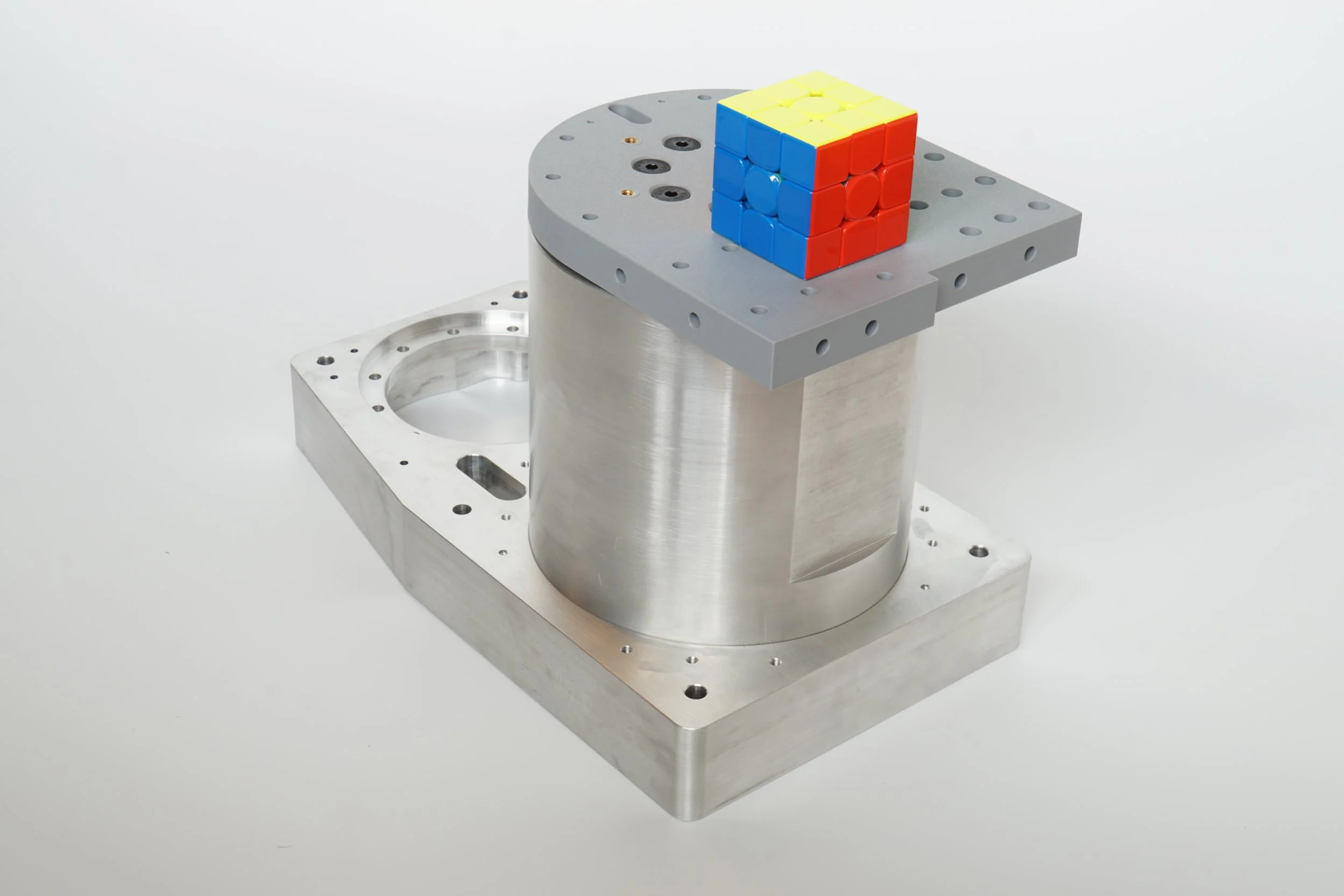

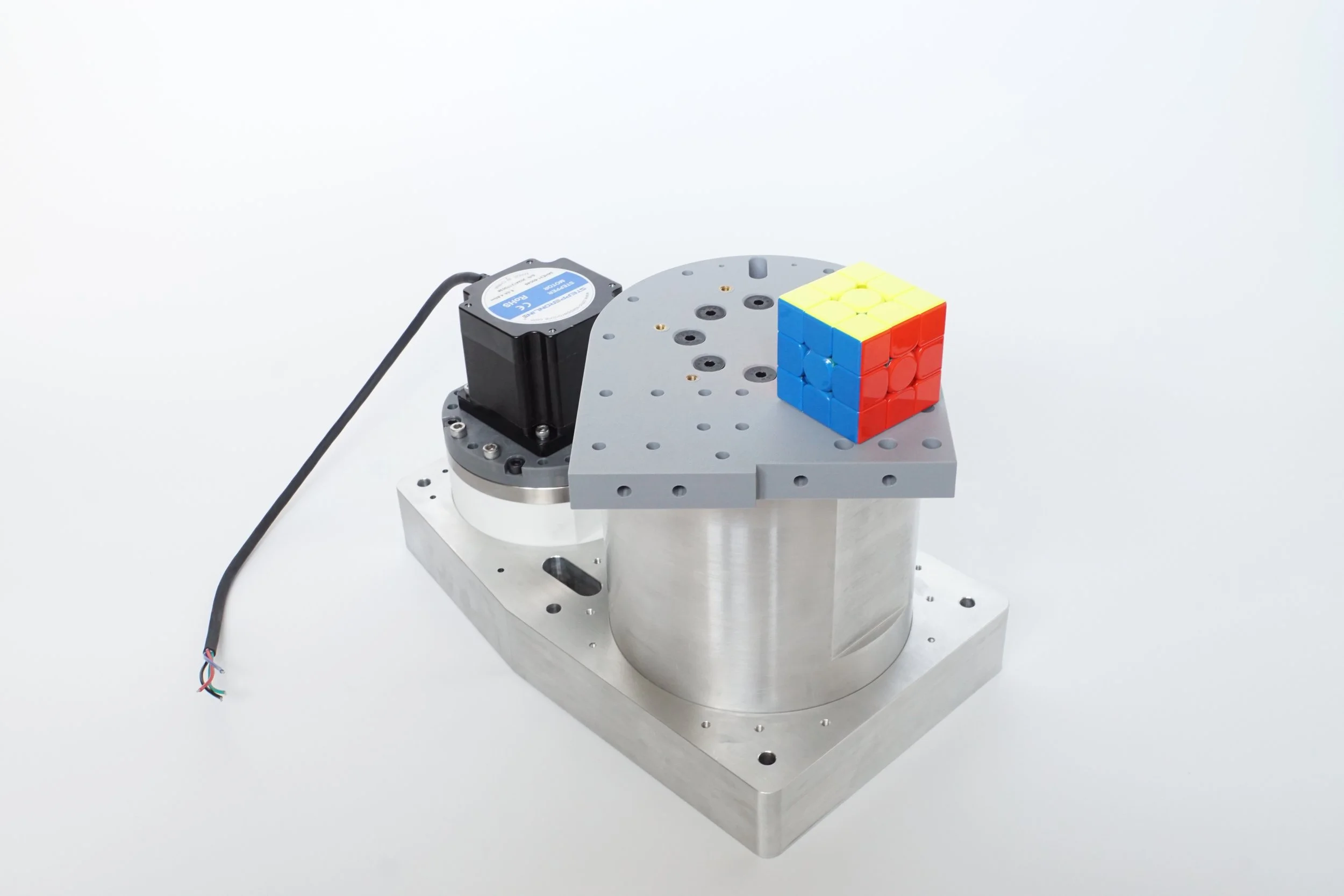

Machined parts

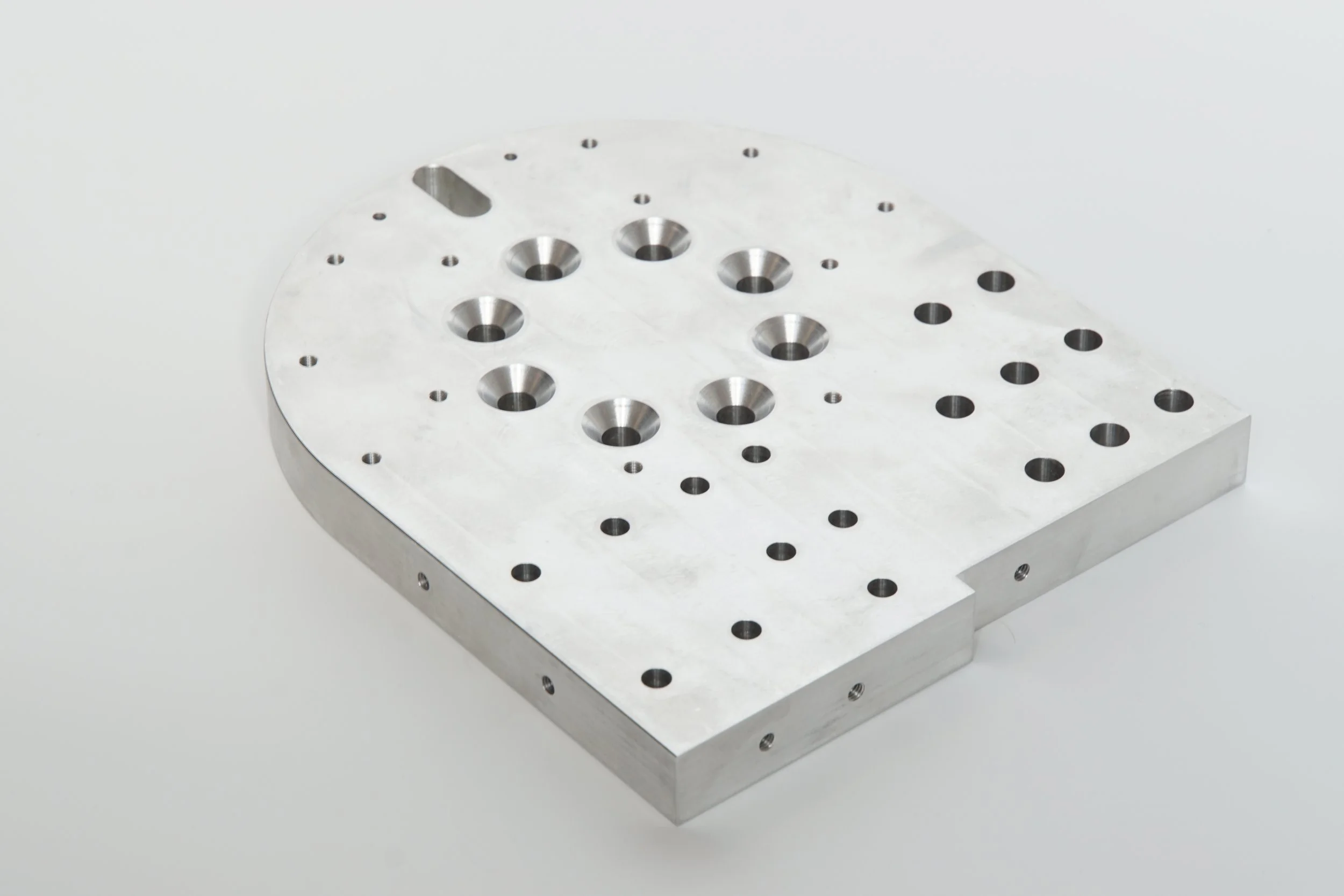

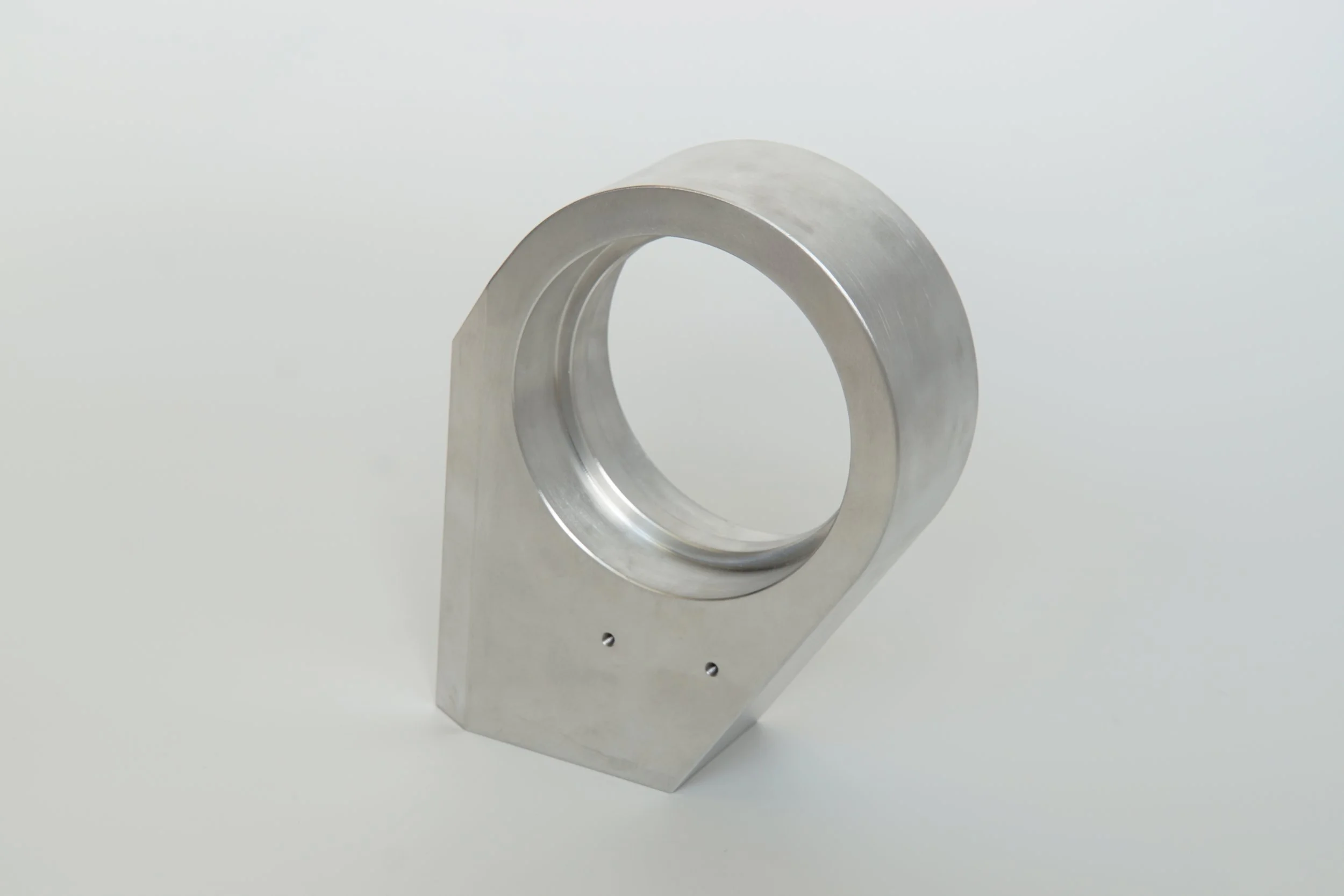

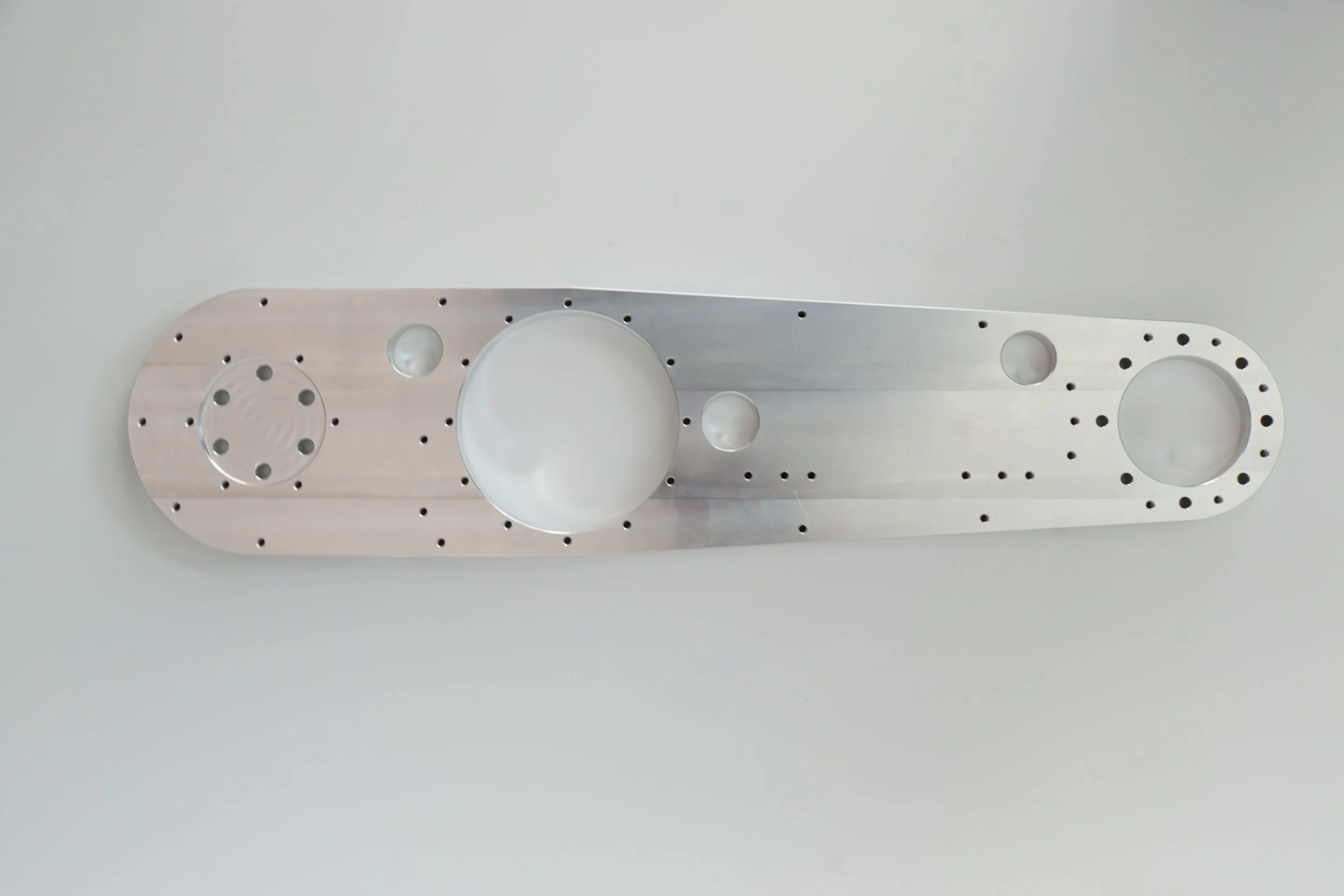

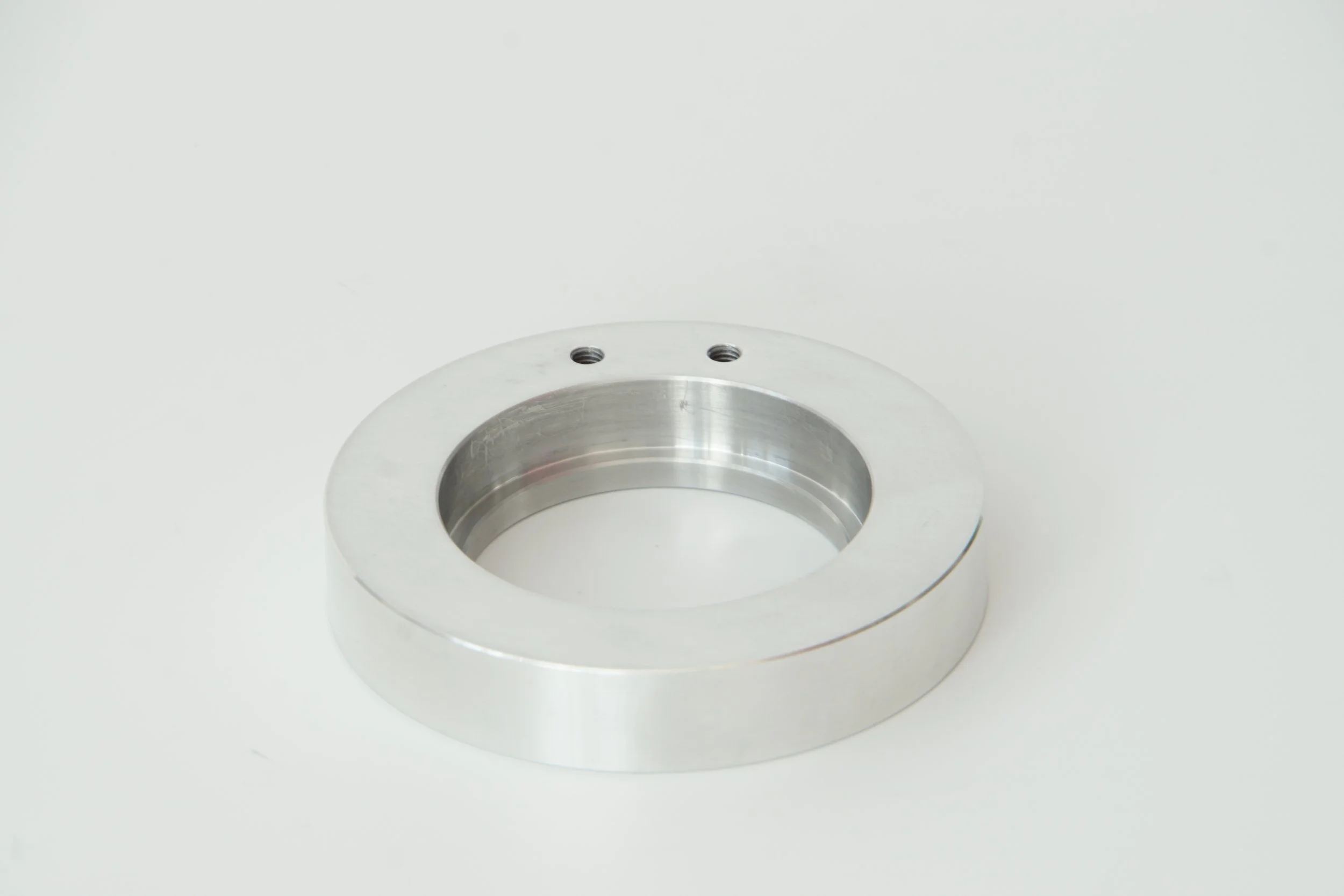

I wanted IRAS to be as rigid and precise as possible, I therefore designed the bottom three joints to be made of machined aluminium. This was new to me, as I had never used custom machined metal parts in my projects. And with the size of the parts and the associated cost this was risky endeavour.

These metal parts were machined by JLCCNC from 6061 aluminium:

These metal parts were machined by JUSTWAY from 6061 aluminium:

Assembly of first, second and third joint

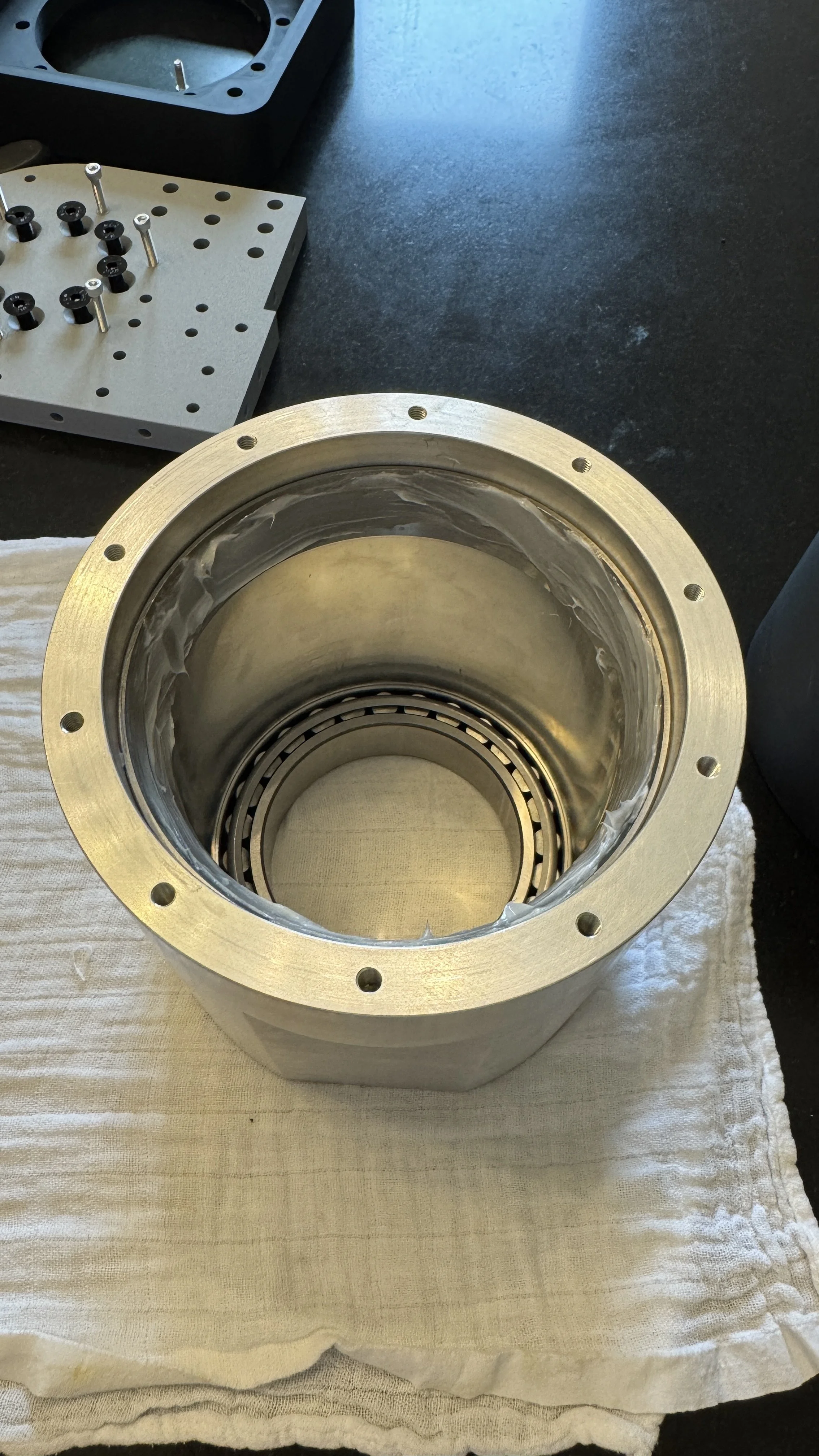

I opted for an interference fit between the bearings and the machined parts to eliminate any play and create a strong connection. The holes in the bearing housing were on purpose 0.05mm undersized and I heated them to around 60°C in the ove, to expand the holes. The outer bearing races were put into the freezer.

Freezing the spindle (top left image) was a mistake, once exposed to air, condesation started to form and create and thick ice layer. I let the part warm up to room temperature and heated the inner bearing races to 85°C and assembly worked perfectly.

Recommendations: Freezing smaller parts is better than big chunky ones, they heat up quicker and leave near to no condensation when mated with warm parts.

first subassembly of the first joint

The assembly of the 2nd joint went similarly by heating and cooling different parts to create a clearance between the mated parts.

When I assembled the parts, I got the bearing and the shaft missaligned and the bearing was stuck (not in the right position).

Using a hammer to remove the bearing had no effect and the bearing didn’t move a bit. However, using an appropriate bearing removal tool, it went pretty smoothly.

The third joints bearings were assembled using the same technique.

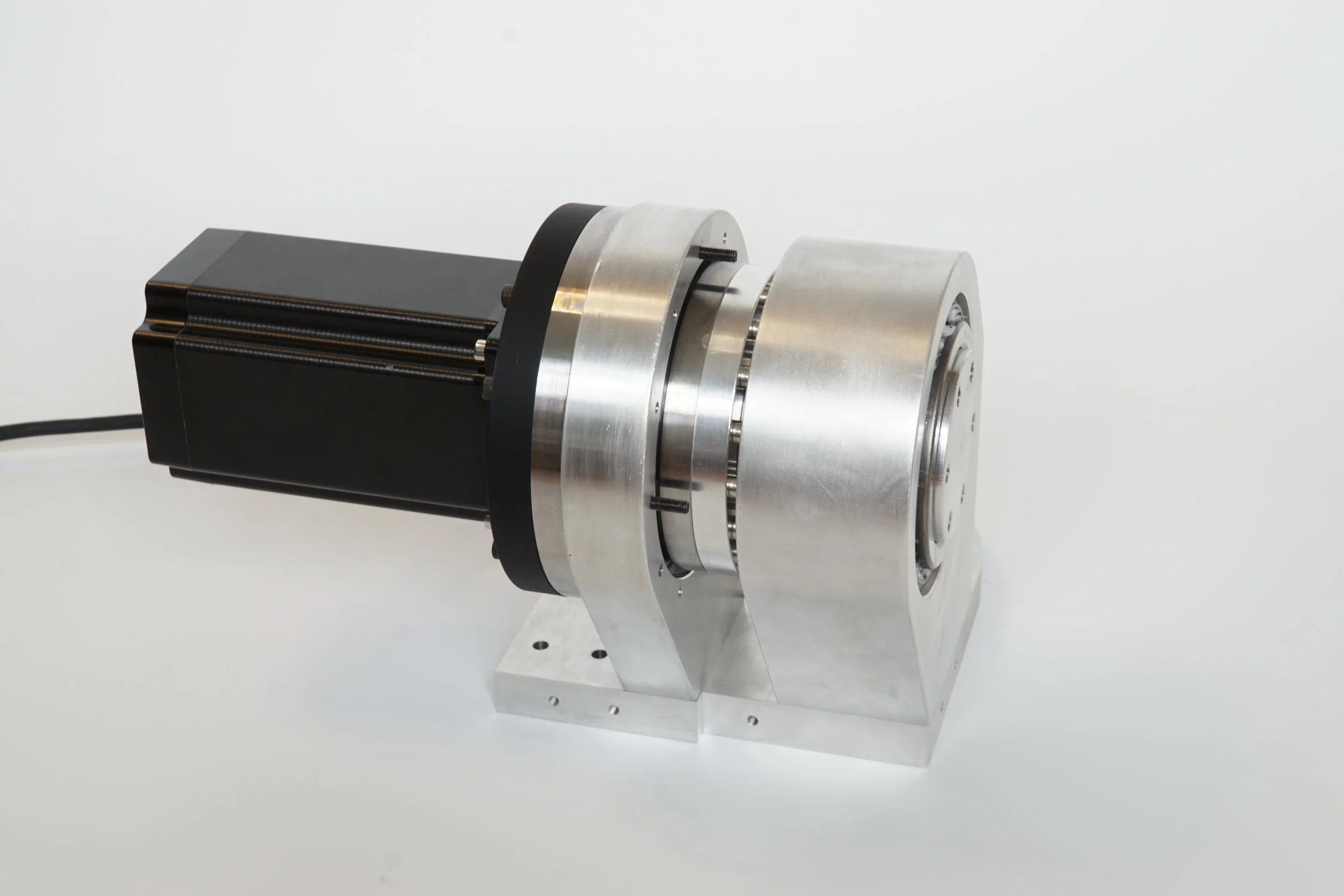

Development of the joint 6 cycloidal drive

The development of my own gearboxes is a crucial aspect of this project.

In the past I have designed multiple gearboxes including planetary gearboxes, strain wavegears and mostly cycloidal gearboxes.

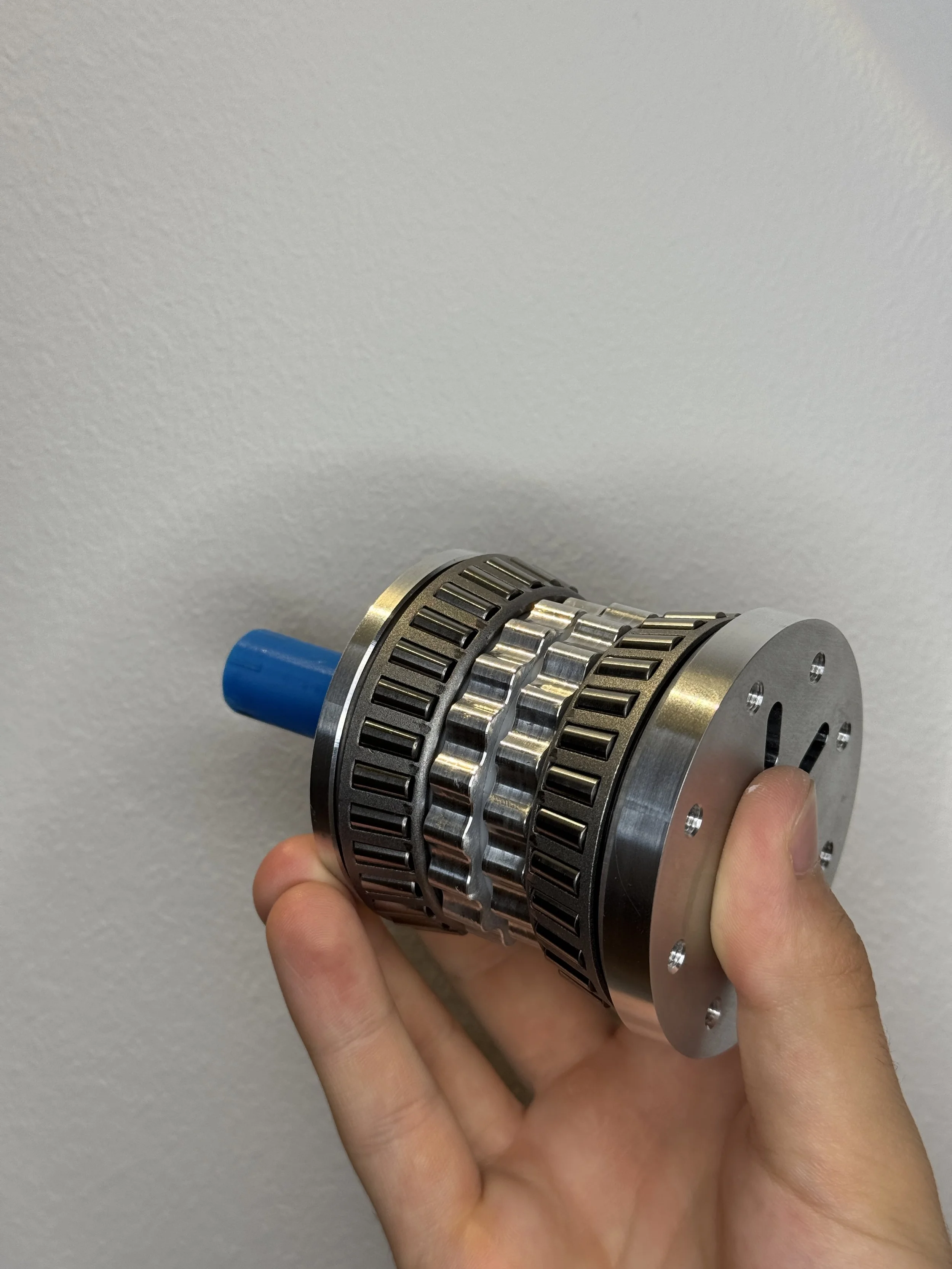

The gearbox of the sixth joint is by far the most compact and best gearbox I have ever designed. Frankly this is the second design of cycloidal gearbox I made for joint 6. The first one had a very simple design where the reduction stage is followed by a set of tapered roller bearings. I use two tapered roller bearings instead of one cross roller bearing as those are very expensive.

All the space between the bearings in image below, is wasted and makes the drive quite bulky. I therefore came up with the idea to have the cycloidal disks be between the bearings and have wasted space.

As a proof of concept, that my design works as intended, I created multiple 3d-printed prototypes.

When my aluminium parts from JLCCNC arrived, I had to do a lot of tuning the radius of the rolling pins, because my 3d prints were not as precise as the metal parts, and I therefore had to alter the design to get a perfect fit.

After about 5 iterations, the cycloidal drive had no backlash at all.

First movement of IRAS

Sponsorships

Thanks to all that support this project, especially JLCCNC and JUSTWAY, who machined all the aluminium parts and Nabtesco who supplied me with two strain wave drives.